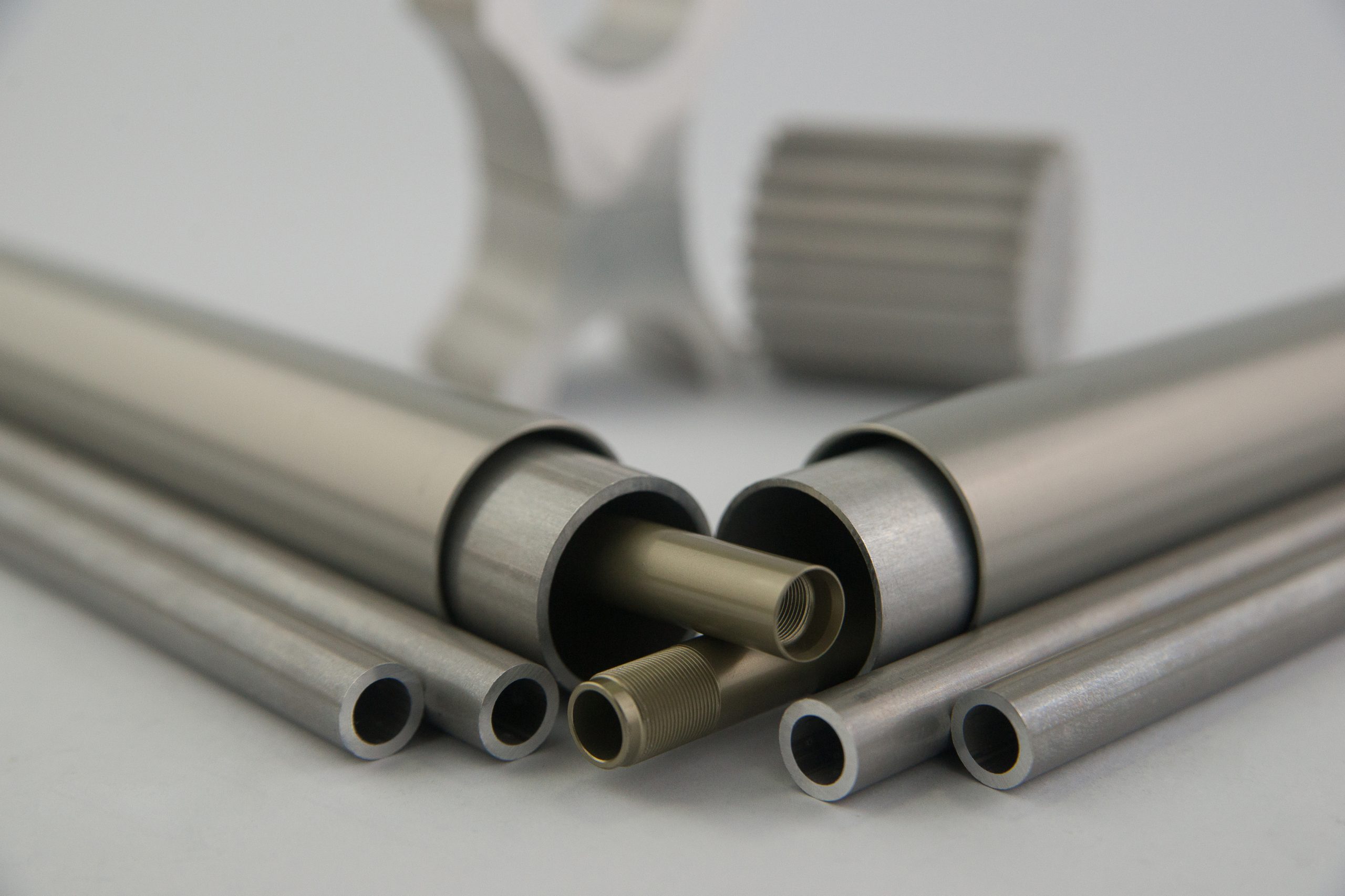

Professional Drawn Aluminum Tubing Manufacturer: AMSpec

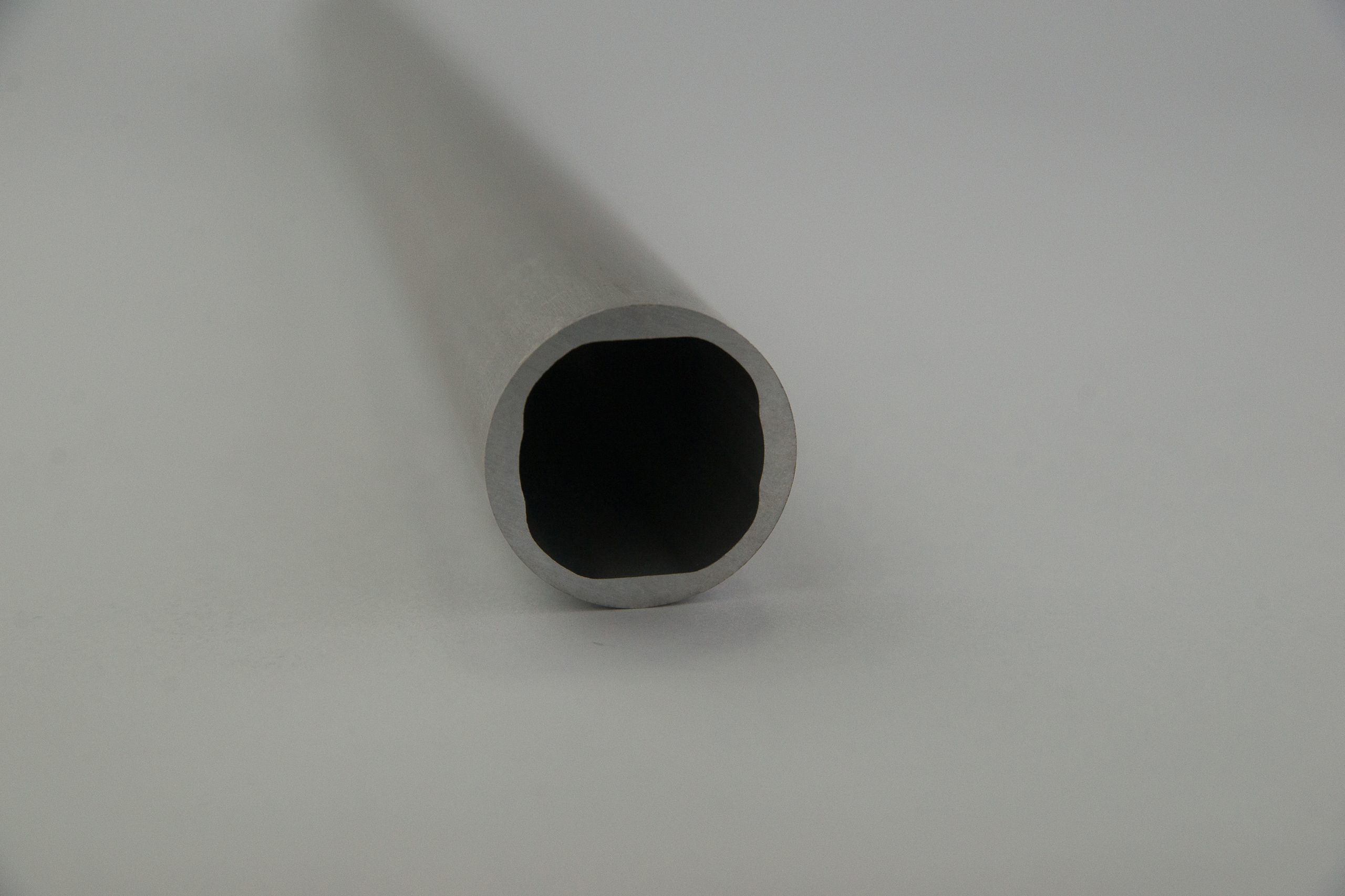

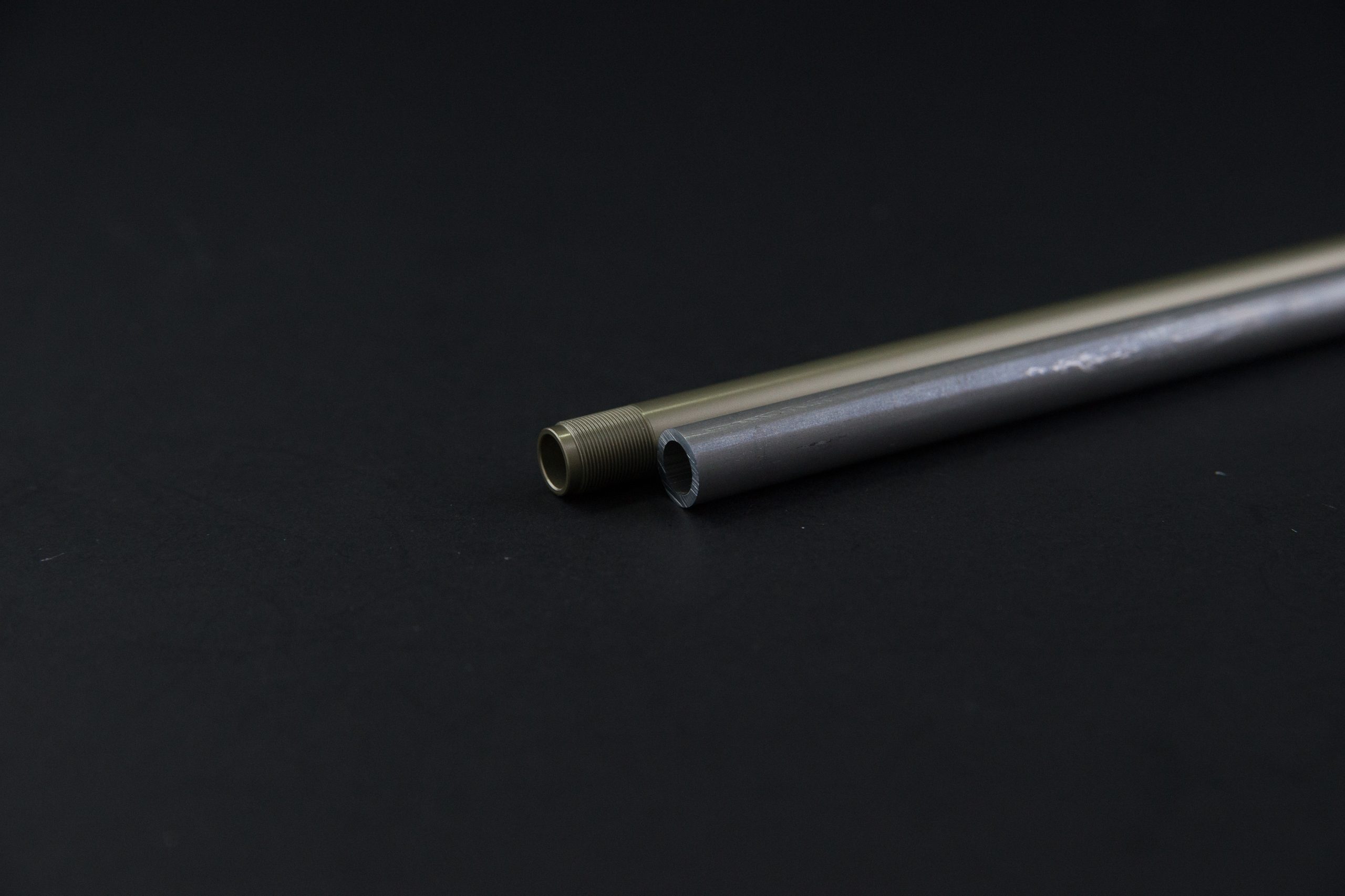

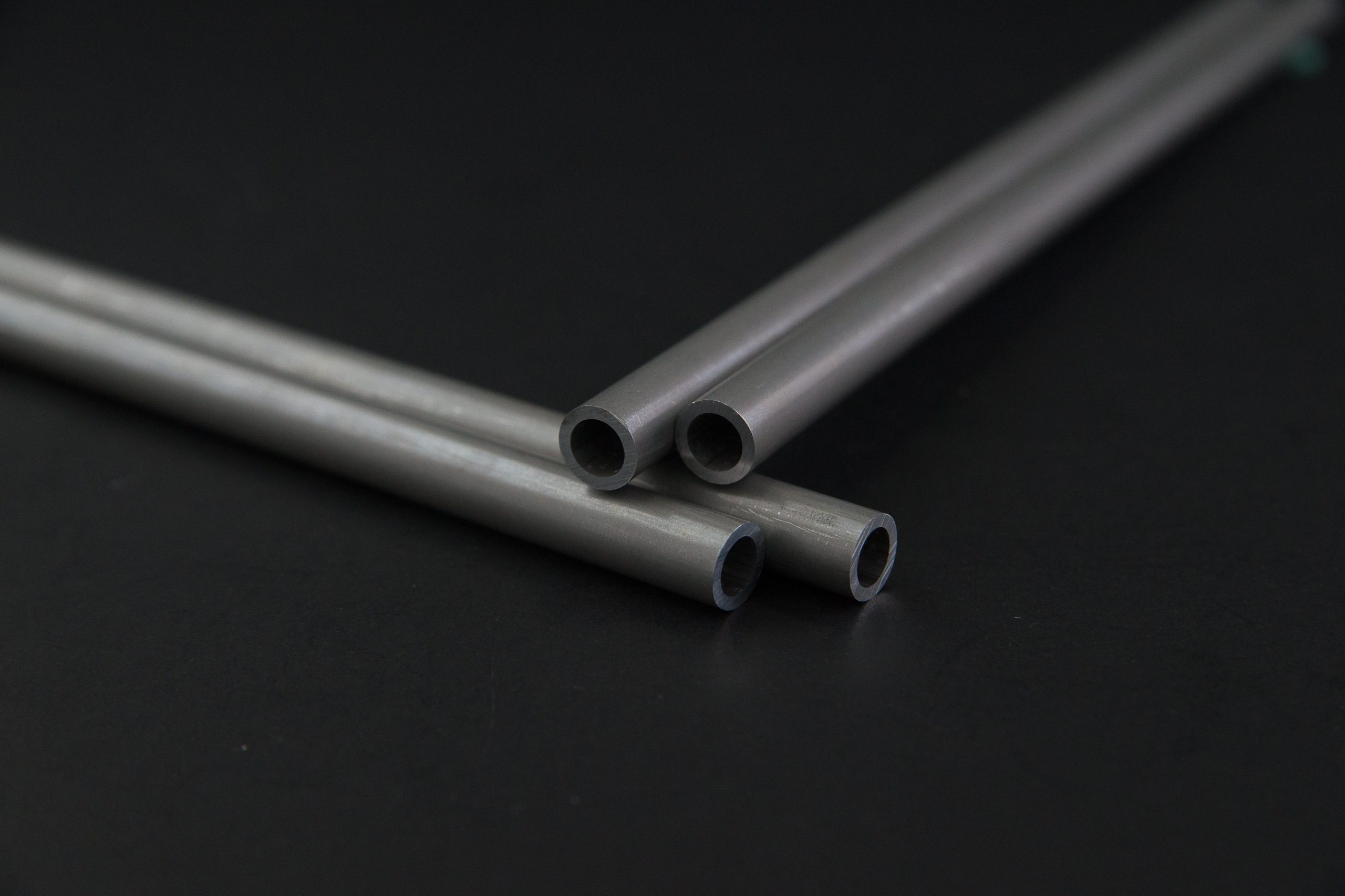

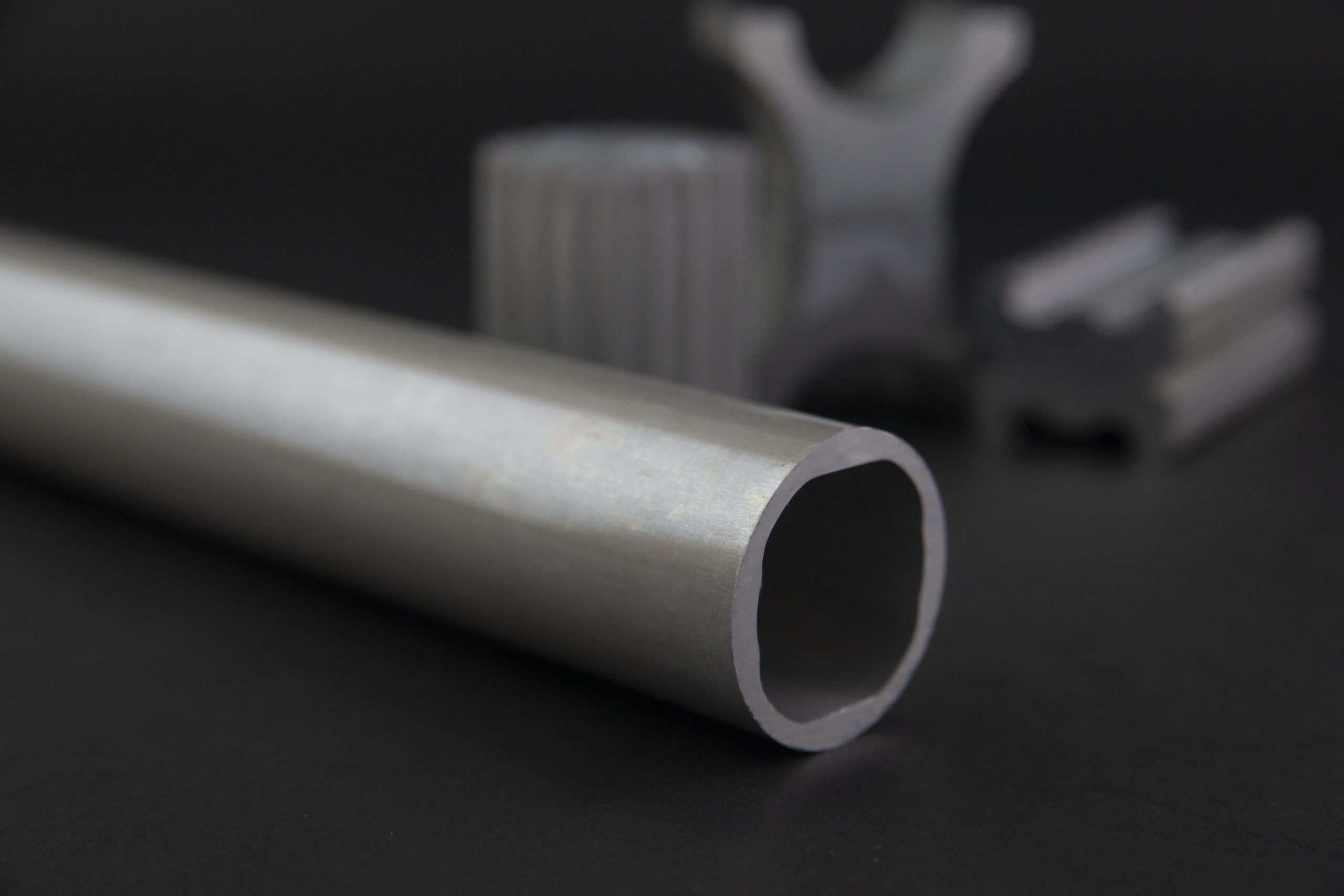

The drawn aluminum tubing machine of AMSpec is designed by drawing tube experts, and assembled by our engineer. Our design concept is to produce the mirror surface and high precise drawn aluminum tubing from our stable extrusion tubes, we overcome the residual stress after heat treatment and optimal alignment process to provide the high precise products.

When we receive the drawing of drawn aluminum tubing from customers, we will focus on the surface roughness and dimension, our goal is to reach the mirror surface and high precise drawn aluminum tubing just like the OPC (Organic Photo-Conductor) tubes of Japan.

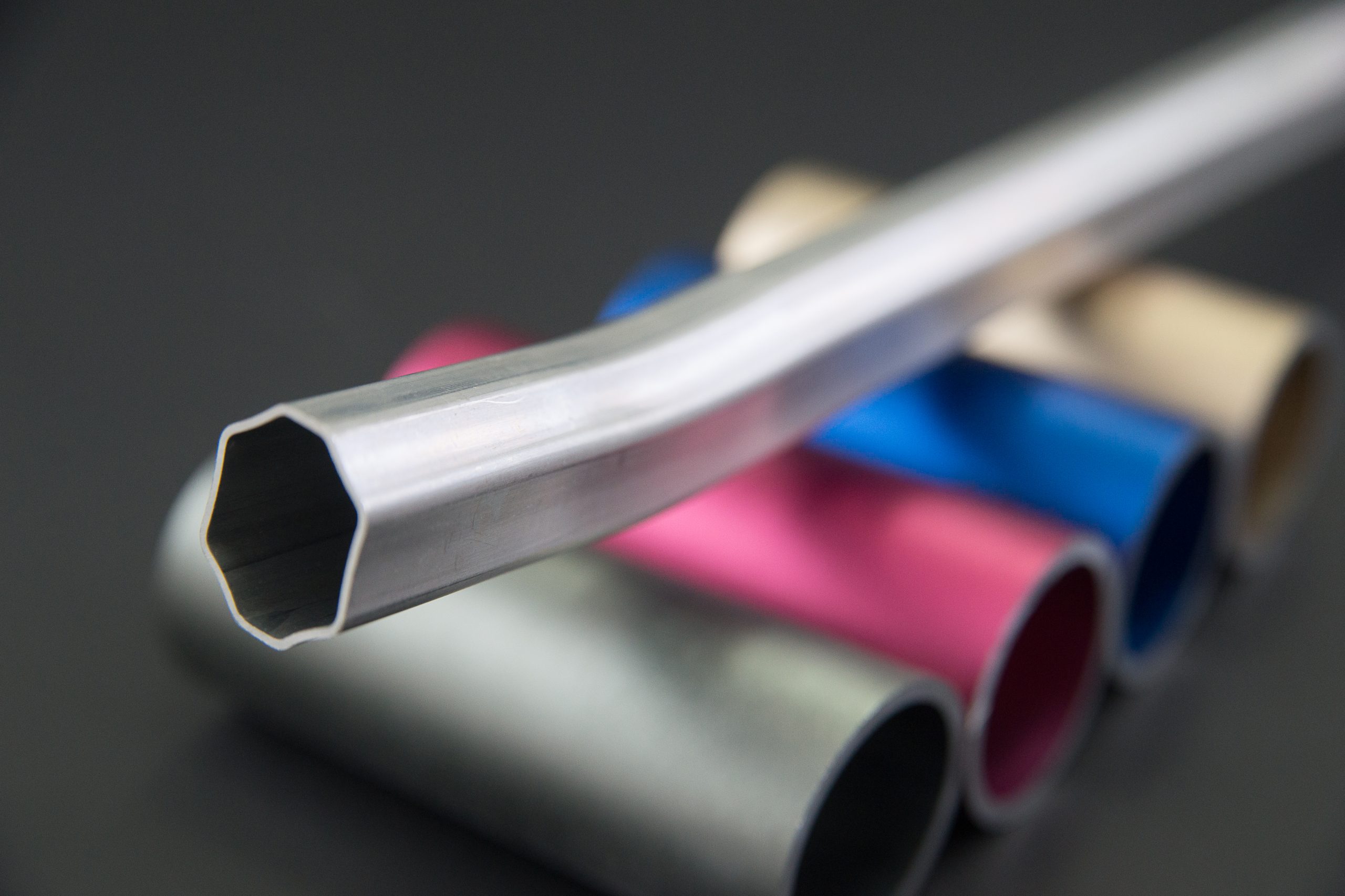

Our R&D team is also actively developing the higher strength 6061 and 7050 grade aluminum tubes or profiles, with precision-designed drawing mold to reach mirror surface and high precise level after drawings. ( <micro inch as target)

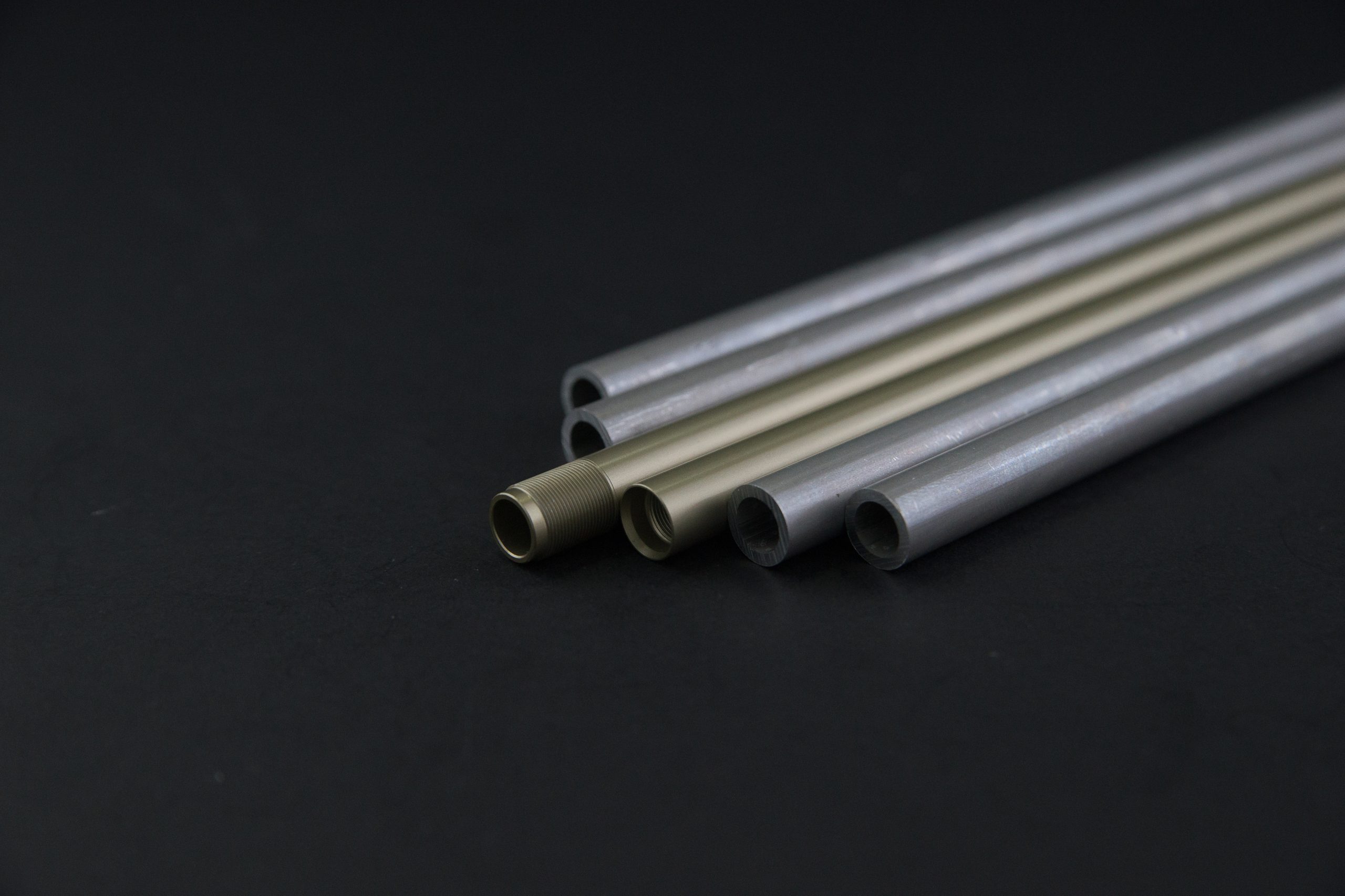

- Alloy: 2xxx、6xxx、7xxx

- Dimensional range: OD 7-80 mm、thickness≧0.7mm

- Tolerances: high-precise drawing tubes ±0.02mm

- Advantage of AMSpec:

- The surface quality of tube is excellent, no cavities, vibration marks, etc. also the surface can reach surface roughness Ra 0.2μm or less.

- Optimize the processing ratio can reach fine grain size.

- Specialized in high strength, fatigue resistance tubes.

- Application: lacrosse shaft, ice axe, bicycle industry, shock absorber, suspension tube, aerospace seating system, medical equipment parts… etc.

Check Other Products of AMSpec >>

Types of Aluminum Alloys & Recommended Applications

Aluminum Extrusion Profile