Weldable Aluminum Alloy

For traditional bicycle frames made with 6061 and 7005 aluminum alloy tubes with typical tensile strengths of 310MPa and 350MPa respectively, its weldability by TIG welding is grade A. The AMSpec team has accepted numerous commissions from famous bicycle frame factories for many years, seeking to enhance the 6000 series frame tube to Duralumin 2000 series aluminum alloy strength along with Grade A weldability. As shown in the table below, 2014 aluminum alloy with tensile strengths of 450MPa and yield strengths of 386MPa are target values of bicycle frame tubes. Improved from 6000 series aluminum alloy, 6xxx-Sc alloy is superior to M6 (6069). The latter has been the main material of most top bike frames for more than 10 years, but the strength is still low. Improvements to 7xxx Alloy, 7xxx-Sc (M7) are highly regarded but the weldability needs to be further improved and the price of Al-Sc series alloys is still very high.

| Alloy | Static Mechanical Property | |||

| TS (MPa) | YS (MPa) | El (%) | Weldability | |

| M6(6069) | 403 | 369 | 9.8 | A |

| 2014-T6 | 450 | 386 | 8 | D |

| 6xxx-Sc | 446 | 390 | 11 | A |

| 7xxx-Sc(M7) | 490-520 | 450-480 | 11-12 | B |

※The testing data will be different based on different specifications.

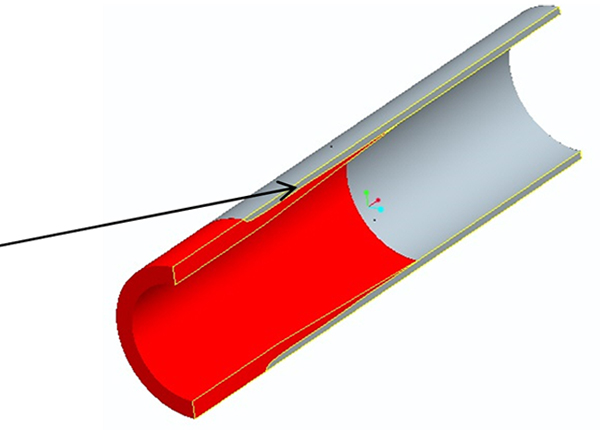

AMSpec has just created a high-strength aluminum alloy tube with a tensile strength of 7050 (TS 600MPa) for the construction of bicycle frames. We have also invented a material which is suitable for welding at the tube ends but features high-strength aluminum alloy characteristics elsewhere. To illustrate with 7×50 / DB (Diffusion Bonding) tube first, note the other end of the tube as shown below, the weldability has reached Grade A along without compromising the high strength of bimetallic tube material.

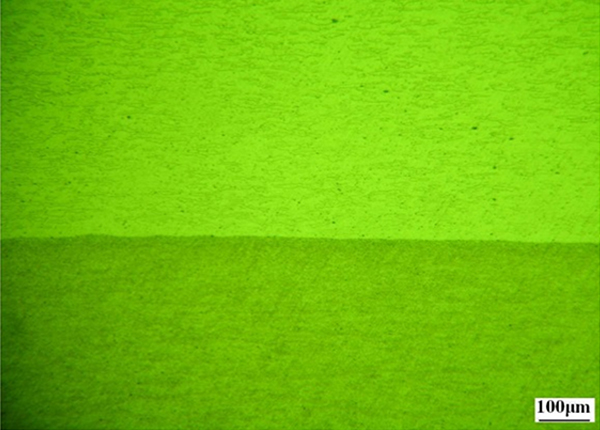

We have achieved another very special product breakthrough by refining 6000 series aluminum alloy whose grain size to below 10μm. In addition to maintaining Grade A weldability, the fatigue strength was significantly improved and the overall result is a product with characteristics close to 6000 series with Sc and Duralumin alloy.