Home / Technology

Technology

6061 and 7075 are often at the top of the list. Both belong to the 6xxx and 7xxx series respectively and are known for their excellent strength-to-weight ratios, machinability, and widespread use across aerospace, transportation, sporting goods, and structural industries. However, the two alloys differ significantly in composition, mechanical behavior, corrosion resistance, and cost.

Both 7050 and 7075 aluminum are high-strength, heat-treatable alloys from the 7xxx series, widely used in aerospace, transportation, defense, and structural engineering. While these two alloys are often compared due to their similar strength-to-weight ratios and mechanical performance, they are not interchangeable.

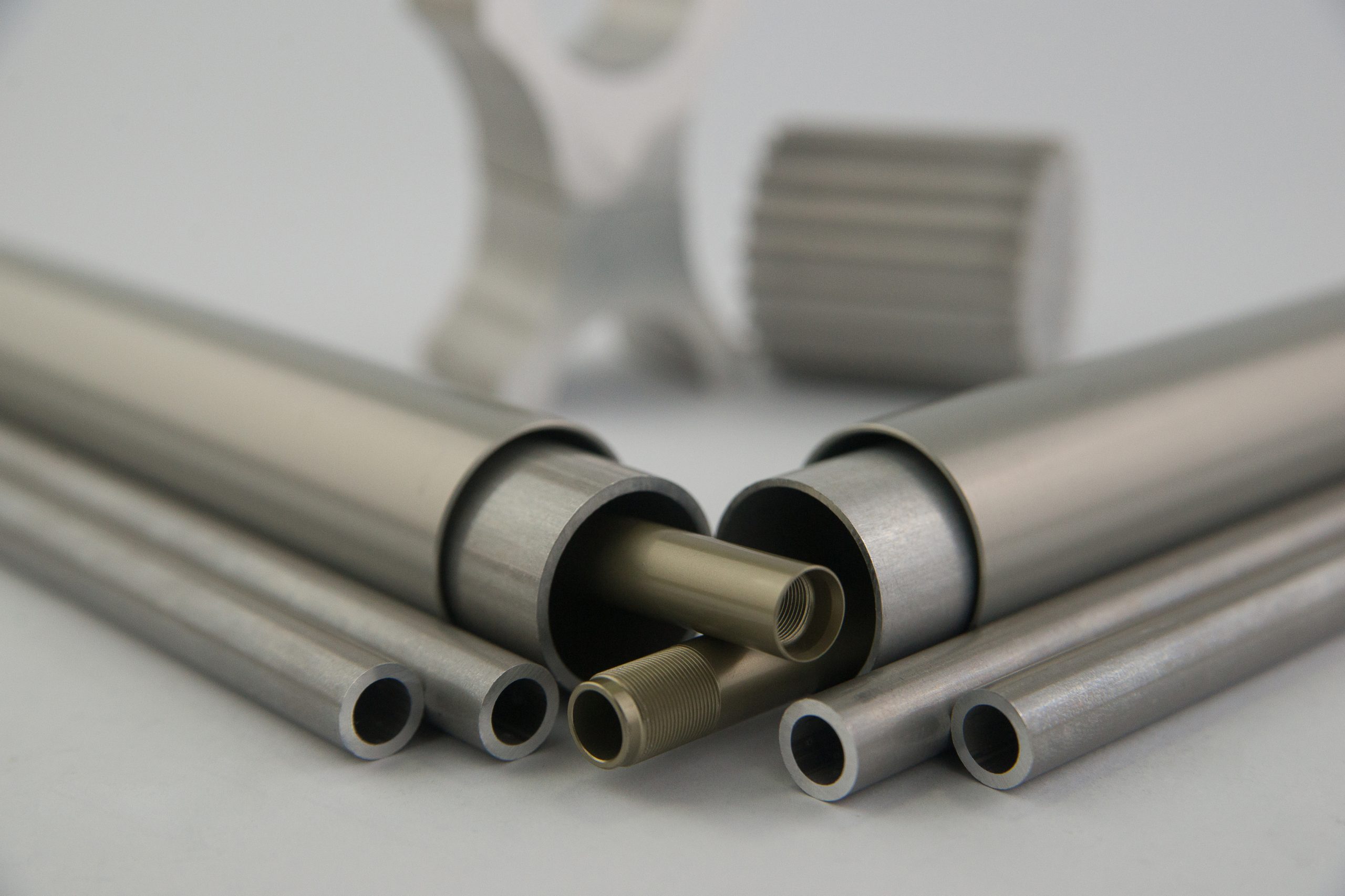

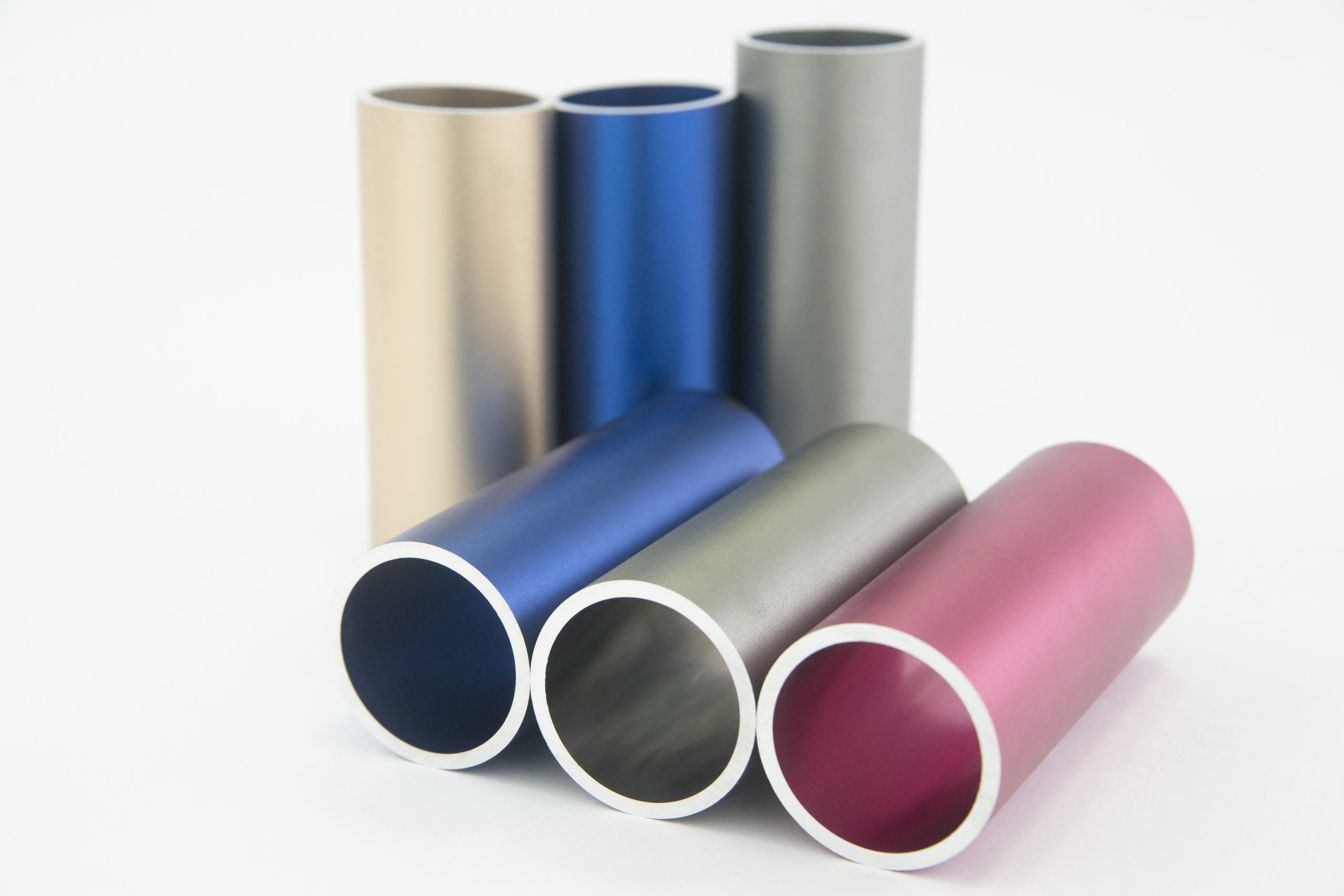

Aluminum is one of the most versatile metals used in modern manufacturing. Its lightweight properties, corrosion resistance, and formability make it ideal across industries. AMSpec specialize in high-precision aluminum alloy tubing and profiles, offering tailored solutions using the full spectrum of aluminum grades.

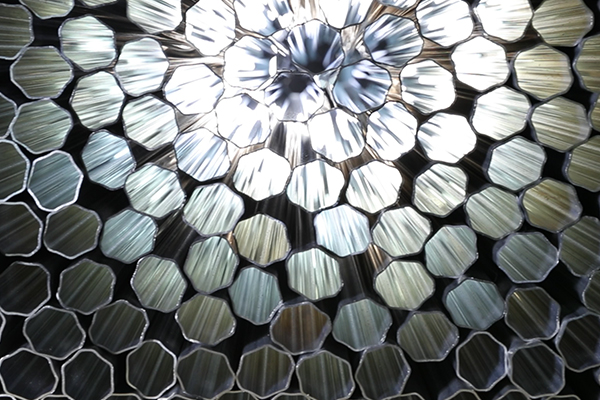

Surface finishing is an essential part of aluminum alloy manufacturing—whether to improve corrosion resistance, refine appearance, or enhance surface performance for downstream processing.

Aluminum is prized across industries for its light weight, strength, and natural corrosion resistance, but that doesn't mean it's completely immune to degradation. To extend the life of aluminum alloy products, especially in outdoor, marine, industrial, or high-moisture applications, it is essential to understand the causes of corrosion and adopt practical prevention methods.

To meet demanding mechanical requirements of aluminum alloy, various hardening techniques can be applied depending on the alloy series and end-use application. These methods enhance aluminum’s strength, wear resistance, and performance in critical environments.