Aluminum alloys are prized for their unique mechanical and physical properties, making them ideal for a wide range of applications. At AMSpec, we specialize in the heat treatment of aluminum alloys, utilizing precise heating and cooling techniques to modify the material’s microstructure. This process enhances strength, durability, and performance, tailored to meet specific project requirements. Unlike steel, aluminum’s lower melting point and higher thermal conductivity demand specialized expertise, which our advanced furnaces and rigorous standards deliver.

Solution Heat Treatment furnace

Compared to the general industrial solution heat treatment, AMSpec will select and setup the parameters for the solution heat treatment of aluminum alloys according to the principle of phase transformation dynamics. The uniform heat convection and the good insulation condition of the furnace results in the accuracy of furnace temperature and it can improve the solid solution degree of alloy elements in the matrix of aluminum alloy. In addition, coupled with the rapid quenching, the precipitation of aluminum alloy can remain at the steady state of super-saturation and can improve the mechanical properties of products after aging.

Solution Heat Treatment Furnace Specifications:

- Furnace type: electrical heating with circulating atmosphere

- Internal space: L1100mm x W900mm x H1100mm

- Number of temperature sensors: 6 pcs

- Max temperature limitation: 560℃

- Heating power: 100kw

- Temperature controller: multi-stage PID control

Aging Heat Treatment furnace

After solution heat treatment of aluminum alloys, the aluminum alloy is strengthening by the artificial aging precipitation in the furnace. The uniform heat convection and the good insulation condition of the furnace results in the accuracy of furnace temperature and it can bring the alloy with high strength and stable mechanical properties.

Aging Heat Treatment Furnace Specifications:

- Furnace type: electrical heating with circulating atmosphere

- Internal space: L44800mm x W1200mm x H1000mm

- Number of temperature sensors: 6 pcs

- Max temperature limitation: 220℃

- Heating power: 75kw

- Temperature controller: multi-stage PID control

Annealing Heat Treatment furnace

The microstructure of aluminum alloys depends on the process of annealing and the cooling rate. At AMSpec, we fine-tune the parameters of heat treatment of aluminum alloys according to the specifications. After annealing, the elongation is recovered and suit for the next stage of working.

Annealing Heat Treatment Furnace Specifications:

- Furnace type: electrical heating with circulating atmosphere

- Internal space: L5000mm x W1535mm x H1000mm

- Number of temperature sensors: 6 pcs

- Max Temperature limitation: 460℃

- Heating power: 220kw

- Temperature controller: multi-stage PID control

THE ADVANTAGE OF AMSPEC OVER OTHER ALUMINUM ALLOYS HEAT TREATMENT COMPANIES.

We set up the aluminum alloy heat treatment equipments including annealing, solid solution, and aging, our purpose is to improve the mechanical properties of aluminum alloy products, also doing an in-house heat treatment can prevent some collision problem while moving the products.

Our heat treatment also meets below standards:

- AMS 2770 Heat Treatment of WroughtAluminum Alloy Parts

- AMS 2772 Heat Treatment of Aluminum Alloy Raw Materials

- AMS 2750 Pyrometry

- AIAG (Automotive Industry Action Group) CQI-9

We have lots of studies for aluminum alloys heat treatment equipment to improve the material mechanical properties, including the parameters of homogenization, in-process, full annealing, solid solution and aging, etc., also developed the technique for micro-characteristic analysis and research of dynamic techniques.

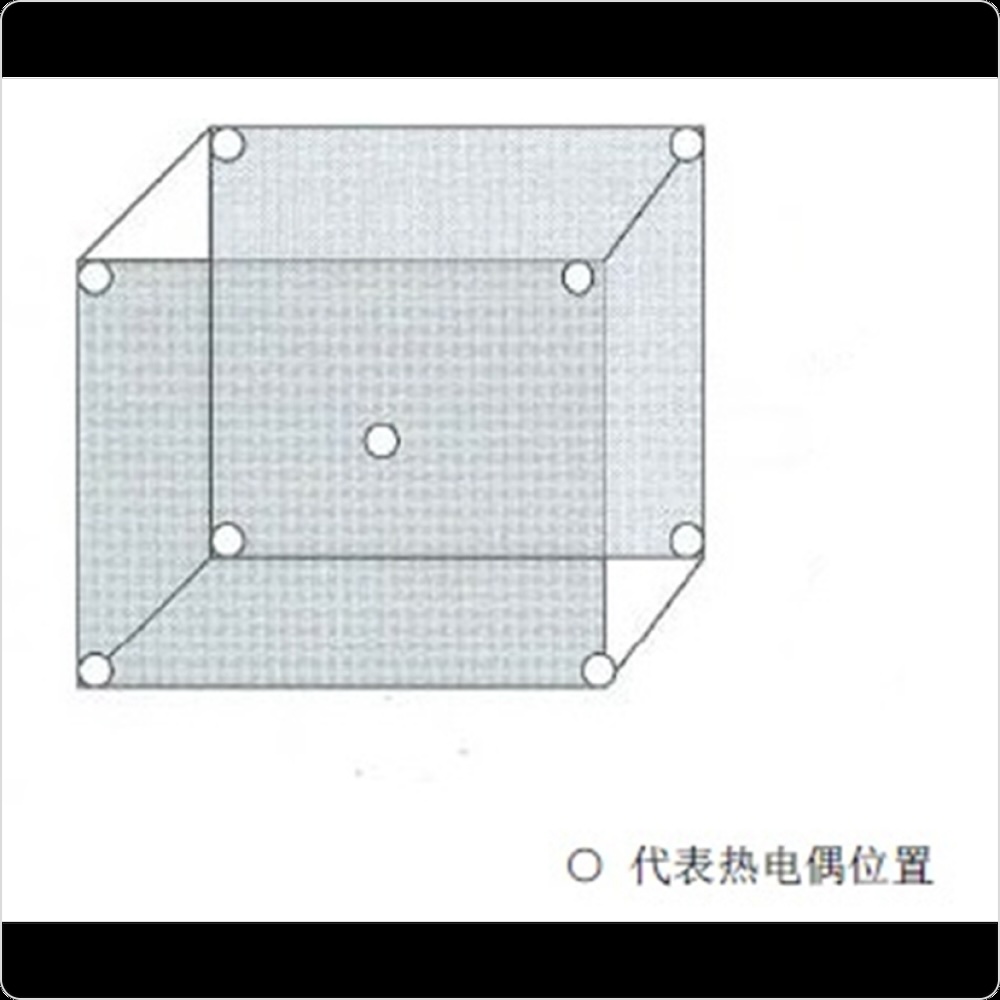

FURNACE TEMPERATURE UNIFORMITY MEASUREMENT

Heat treatment furnace system accuracy test (SAT):

To compare the temperature difference, the qualified temperature probe must be placed within 2 inches of the pre-calibrated control thermocouple. (calibrated temperature value should be refer to use the temperature range in order to establish a linear relationship.)

Heat treatment furnace temperature uniformity evaluation (TUS) level 2:

This measurement can be separated into empty furnace and loading furnace. The loading test can directly reflect the actual temperate which the products are really heated. The different shapes of products will result in different wind directions.

At AMSpec, our advanced heat treatment of aluminum alloys processes allow us to precisely enhance the strength, ductility, and durability of aluminum alloy products. Whether your project requires improved mechanical properties or tailored material characteristics, AMSpec’s in-house expertise delivers reliable solutions. Contact us to discuss how our heat treatment capabilities can meet your specific manufacturing needs.

Explore AMSpec Aluminum Alloy Products >>

Types of Aluminum Alloy & Recommended Applications

Aircraft Extrusion & Tubing | Aerospace Grade Aluminum Alloy