Strongest Aluminum Alloy – High-Strength Solutions

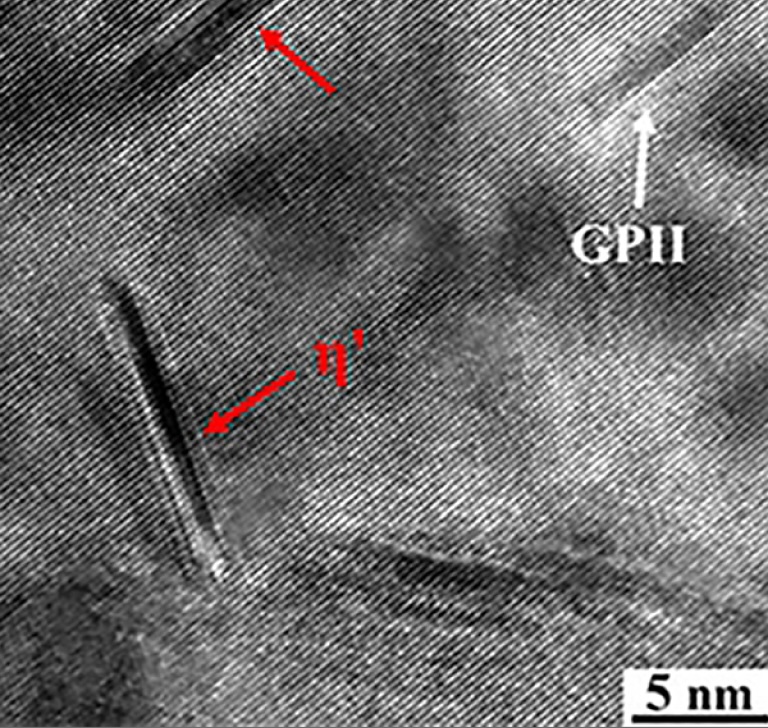

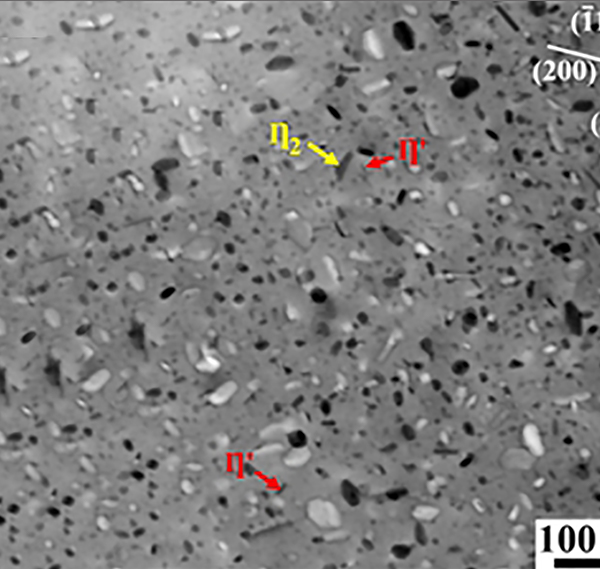

※Work with the department of materials science and engineering, National Taiwan University to study the microstructure of the 7000 series high strength aluminum alloy and the result as below.

Strongest Aluminum Alloy by AMSpec

Due to the demand for high-strength aluminum alloy seamless tubes for bicycle forks and baseball bats, AMSpec’s technical team established the 7050-T76 strength class seamless tubes production technology in 2008, which were among the strongest aluminum alloys that AMSpec produced. Quickly followed by higher strength and fracture toughness of 7150-T7x and T6x alloys thus achieving industry’s top level of fatigue resistance. Also, we greatly improved both bending deformation and impact resistance in 7055, 7068 class materials.

To optimize alloy design for the strongest aluminum alloys possible, micro-alloys incorporating elements are also under development. The following 7250, A600Sc, A800Sc alloys that optimized by AMSpec, can have reached tensile strengths of 700MPa or above, making them among the strongest aluminum alloys we made. We make these high-strength aluminum alloys by using highly purified casting techniques, addition of micro-refined elements and supersaturated alloy modification to achieve the target of ultra-high strength.

In plastic processing technology, we mainly use AMSpec-developed extrusion mechanisms to achieve excellent results with our multi-pass extrusion process capability (Severe Plastic Deformation, SPD). With the development of especially fine crystalline materials and heat treatment technology, material characteristics can far surpass the limits of traditional aluminum alloys.

AMSpec 7250, A600Sc, A800Sc alloy bar, its typical tensile properties.

| Alloy | Static Mechanical Property | ||

| TS (MPa) | YS (MPa) | El (%) | |

| A800Sc | 752 | 716 | 8 |

| A600Sc | 735 | 700 | 8 |

| 7250 | 720 | 680 | 12 |

※Work with the department of materials science and engineering, National Taiwan University to study the microstructure of the 7000 series high strength aluminum alloy and the result.

Learn More About Our Products >>

Aluminum Extrusion Tube & Tubing Manufacturer

Custom Aluminum Extrusion | OEM/ODM Service