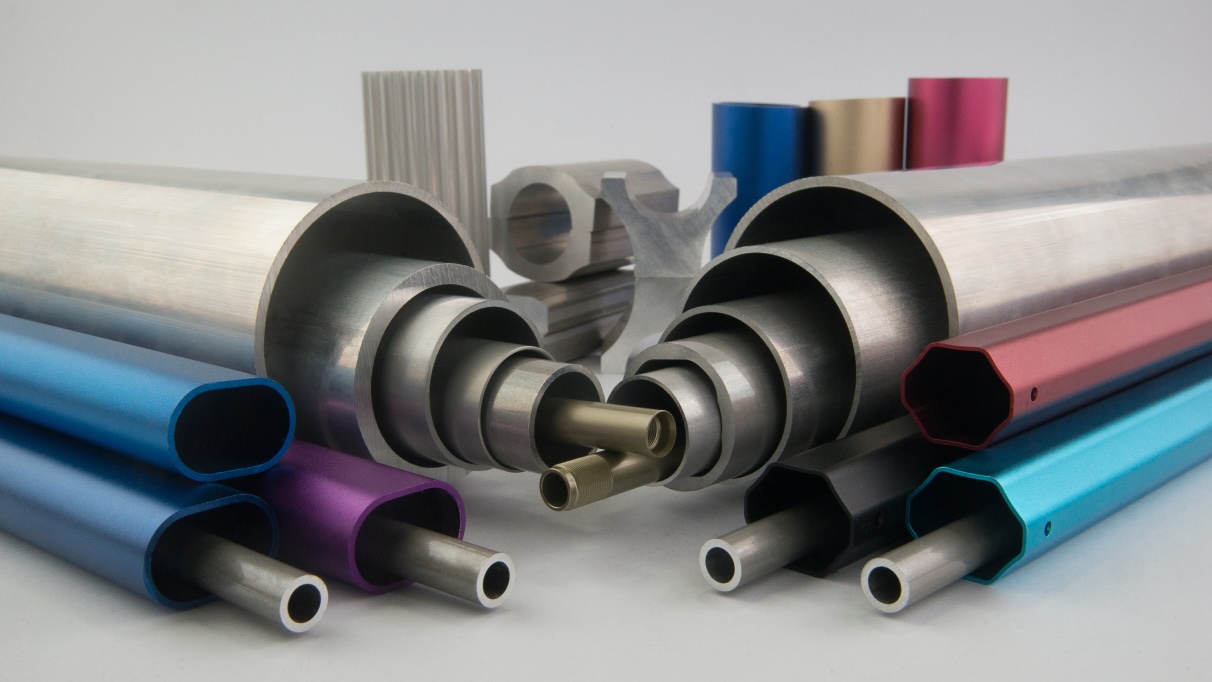

A series of commercial aluminum-copper-magnesium alloys have been developed since the 1930s, of which 2024 and 2014 are the most widely used. The 2014 alloy is different from the 2024. In addition to different ratios of copper-magnesium-manganese alloys, silicon is also added to increase the aging effects of magnesium-silicon (Mg2Si). It has higher strength than original Duralumin (2017 alloy). 2014 aluminum alloy has good ductility and workability, making it suitable for aircraft and other heavy-duty structural uses. The alloy can be made into sheets, plates, rods, tubes, wires, extruded profiles and forgings. To increase the corrosion resistance of sheets and plates, these products can be clad with 6003 or 6053 aluminum alloys.

The 2014 aluminum alloy can be formed in the quenched state and then artificially aged to the T6 state, which is very conducive to the operational convenience of the forming process. The quenching operation should be carried out as quickly as possible. Because if the cooling rate is slow, segregation may occur, resulting in a decrease in corrosion resistance. Its resistance to stress corrosion in the short transverse direction is poor.

A series of commercial aluminum-copper-magnesium alloys have been developed since the 1930s, of which 2024 and 2014 are the most widely used. The 2014 alloy is different from the 2024. In addition to different ratios of copper-magnesium-manganese alloys, silicon is also added to increase the aging effects of magnesium-silicon (Mg2Si). It has higher strength than original Duralumin (2017 alloy). 2014 aluminum alloy has good ductility and workability, making it suitable for aircraft and other heavy-duty structural uses. The alloy can be made into sheets, plates, rods, tubes, wires, extruded profiles and forgings. To increase the corrosion resistance of sheets and plates, these products can be clad with 6003 or 6053 aluminum alloys.

The 2014 aluminum alloy can be formed in the quenched state and then artificially aged to the T6 state, which is very conducive to the operational convenience of the forming process. The quenching operation should be carried out as quickly as possible. Because if the cooling rate is slow, segregation may occur, resulting in a decrease in corrosion resistance. Its resistance to stress corrosion in the short transverse direction is poor.

| Main composition | Cu | Mn | Si | Mg | Al |

|---|---|---|---|---|---|

| 2014 | 4.5 | 1 | 1 | 0.5 | Balance |

| 2014composition (wt.%) | Min | Max |

|---|---|---|

| Cu | 3.90 | 5.00 |

| Mg | 0.20 | 0.80 |

| Mn | 0.40 | 1.20 |

| Fe | -- | 1.00 |

| Si | 0.50 | 1.20 |

| Zn | -- | 0.25 |

| Cr | -- | 0.10 |

| Ti | -- | 0.15 |

| Other impurities | ||

| each | -- | 0.05 |

| total | -- | 0.15 |

| Al | Balance | |

Mechanical properties:

| Alloy | T.S. (MPa) | Y.S. (MPa) | Elongation (%) | Density (gcm3) |

|---|---|---|---|---|

| 2014-T62 | ≥379 | ≥365 | 7 | 2.80 |

Application:

Since 2014 alloy has good formability, it is ideal for application to bicycle handlebars. In aerospace, it is also often used in aircraft and heavy structures. In addition, it is also commonly used in bridges, truck frames, rivets and structural accessories.

References:

1.AIWT, Aerospace Structural Metals Handbook, Nonferrous Alloys, 2014Al

2.Matweb, datasheet.

Standard:

AMS 4153